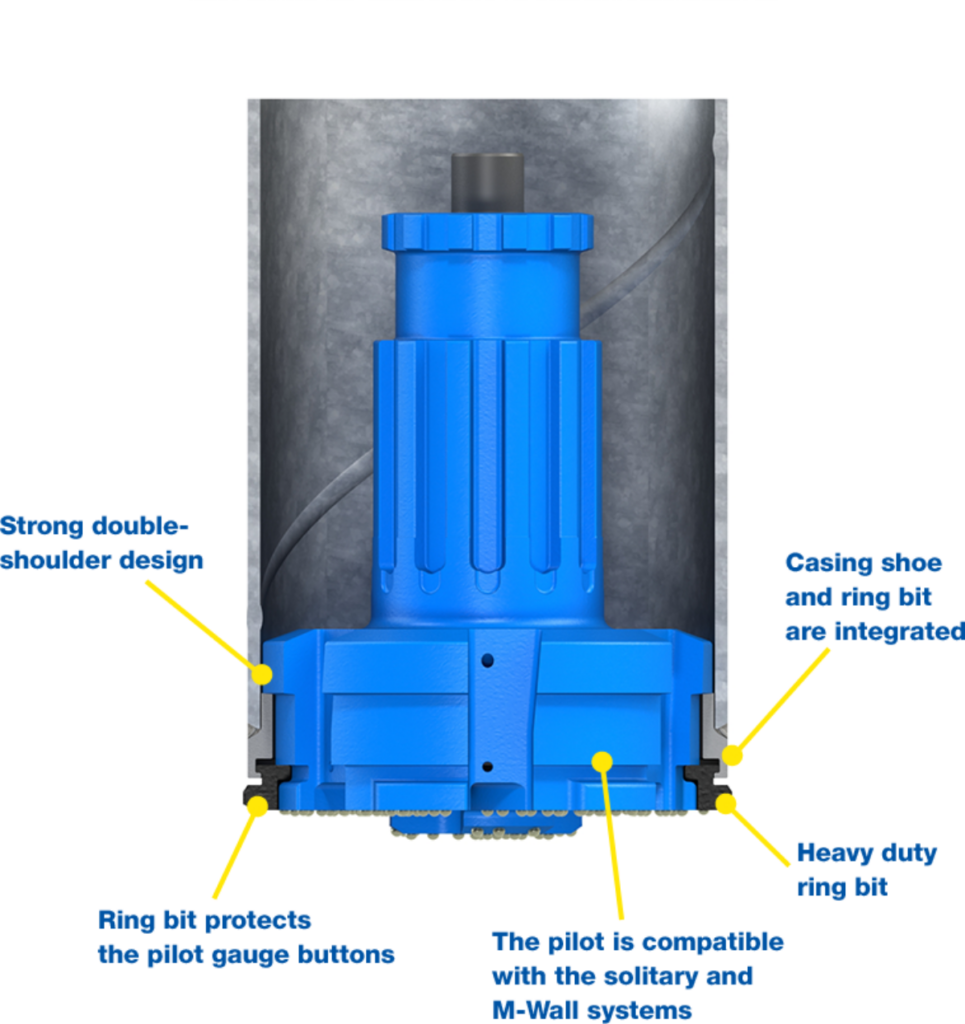

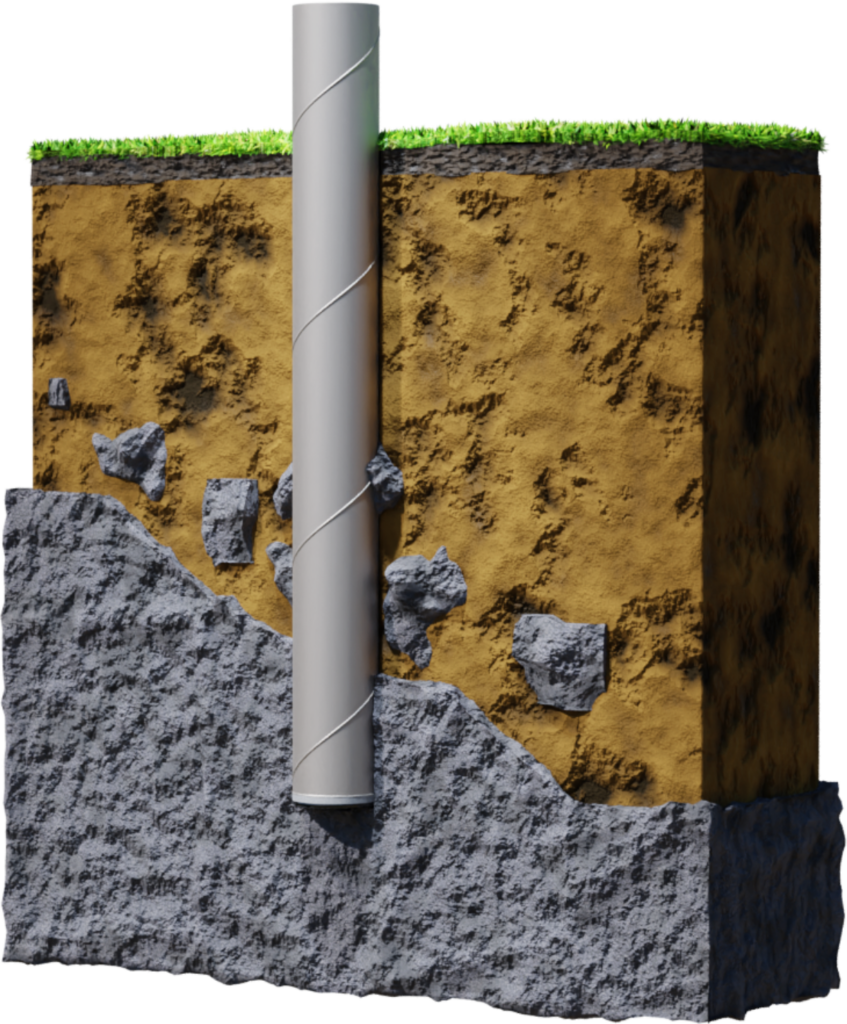

Integrated ring bit systems, divided into small and large designs, are designed for drilling end-bearing piles through overburden into bedrock. The system can drill straight and inclined piles through boulders and rock layers and it easily manages situations where the bedrock itself is inclined. The heavy duty ring bit is integrated into casing shoe, which makes it safe to drill in loose ground and over water. The large size allows for double-shoulder design.

The large integrated system is available from 323 to 1 524 mm casings and for all major shank designs. It uses Spiral Flush technology, offering class-leading safety in overburden drilling.

Download the pdf data sheet for detailed information and measurements.

Integrated ring bit system is our most recommended system. It is often used with end-bearing piles. These, in turn, are used in projects where casings resting in bedrock are calculated to take part of the load together with the reinforced concrete. This way, the amount of rebar steel inside the casing can be reduced.

The benefit of integrated system over solitary system is that it is safe to operate over water, eliminating the risk of accidentaly dropping and loosing the ring bit.

All Mincon casing systems are made with passion to drilling.

Ask for a quote and our geotechnical expert will get back to you as soon as possible.

Mincon Group plc is a global engineering business specialising in the design, development, manufacture, and service of rock drilling tools for a variety of applications.

Originally founded in 1977 in Shannon, Ireland, it now has a worldwide presence, with customer service centres and factories across the Americas; Europe and Middle East; Africa, and Asia Pacific.

[categorytree]